Mold components in precision machining

Nov 01,2021

Mold accessories refer to the general term for metal components specifically used in the mold industry—whether in stamping dies, plastic molds, or FA automation equipment. Dongguan Shilihe Mechanical & Electrical Equipment Co., Ltd. specializes in custom machining of tooling fixtures and precision parts based on customer-provided drawings, positioning itself as a leader in Dongguan's precision machinery manufacturing sector. Among the mold accessory inserts, which products does Shilihe offer with particularly strong expertise?

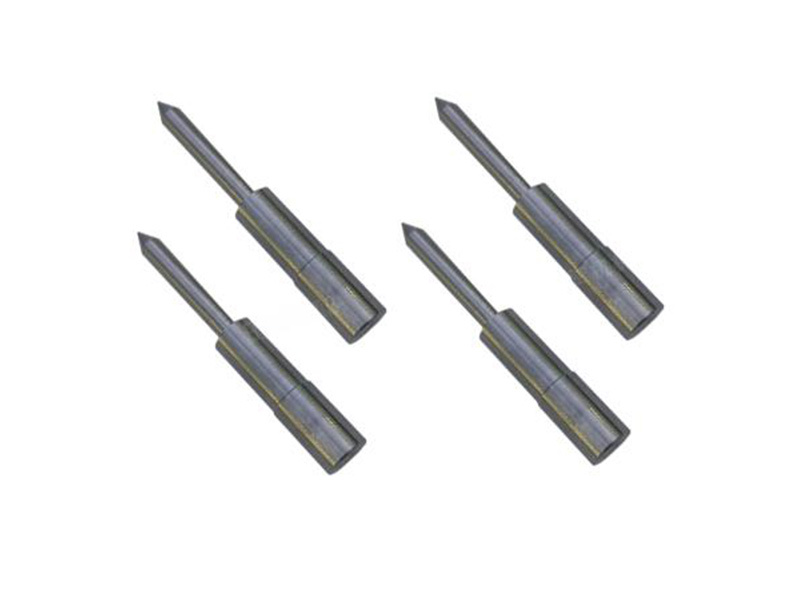

Mold components include common types such as ejector pins, punches, guide posts, guide bushings, push pins, sleeve cylinders, ball cage assemblies, oil-free guide bushings, oil-free slides, and guide post assemblies. These components primarily fall into three main categories: first, plastic mold accessories; second, metal stamping mold accessories; and third, non-standard automation equipment parts.

An insert refers specifically to an irregularly shaped mold component designed to be embedded within a mold, serving the critical function of securing the template and filling the space between templates. Inserts can come in square, round, or sheet-like forms, but they demand exceptionally high precision. Typically, inserts are not mass-produced—they are custom-made according to the specific requirements of the mold. They play essential roles such as aiding venting, simplifying machining processes, enabling easy replacement, and ensuring precise control over critical dimensions.

Previous:

Contact Us

Email:

jywj_cai@vip.163.com

Phone/WeChat:

0512-66181213

Address:

No. 37 Chunfeng Road, Xiangcheng District, Suzhou City, Jiangsu Province, China